JK-2030 Double-Head Stone Engraving Machine For 3D Relief and Tombstone Carving

For years, the stone processing sector has grappled with slow turnaround times and inconsistent precision in 3D relief carving and tombstone customization—especially when working with hard materials like granite and marble. That changed when Jiahe CNC Router(Shandong)Co.,Ltd., a prominent provider of stone processing solutions, integrated its self-developed JK-2030 double-head stone engraving machine into its production line. This move has not only solved long-standing efficiency issues but also elevated the quality of its 3D relief and tombstone products, marking a new chapter for the company's service capabilities.

Efficiency Leap: Cutting Production Time by Half

Prior to adopting the JK-2030, Jiahe relied on single-head engraving machines for its core projects—from intricate 3D floral reliefs on marble wall decorations to personalized tombstone carvings (including lifelike portraits, epitaphs, and decorative borders). A standard 1.2m×0.8m granite tombstone, which requires 3D portrait relief (with a maximum depth of 5mm) and precise text engraving, would take 7–9 hours to finish with a single-head device. For large-scale orders, such as a batch of 40 tombstones for a local cemetery, production cycles often dragged on for 2 weeks or more, leading to tight delivery schedules and customer dissatisfaction.

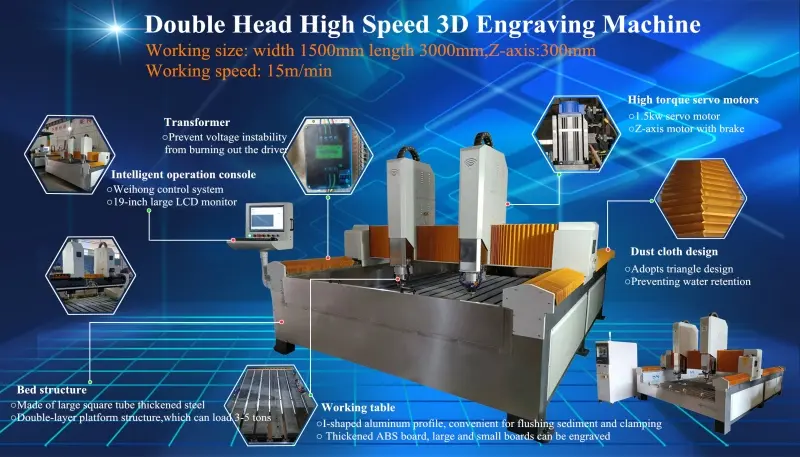

Key Features of JK-2030: Built for Stone Processing Needs

What sets the JK-2030 apart in the market? Its design directly addresses the unique challenges of 3D relief and tombstone carving:

Flexible dual-task operation: The CNC system supports both "same-program sync" (ideal for batch tombstone production) and "different-program work" (perfect for mixing 3D relief and text carving), eliminating downtime between job switches.

Hard material compatibility: With 8kW spindles delivering high torque, the machine easily cuts granite (Mohs hardness 6–7) and marble. Its water-cooling system prevents spindle overheating during long 3D carving sessions, extending equipment lifespan.

Effective dust control: A built-in dual-port vacuum dust collector (one port per head) reduces stone dust by over 85%, improving workshop air quality and reducing cleanup work— a significant upgrade from the messy aftermath of single-head machines.

3D design integration: The JK-2030 works seamlessly with popular 3D software like ArtCAM and Type3, and can import scanned data (such as customer portrait photos) to create accurate 3D relief paths, ensuring tombstone portraits are realistic and true to the original.